Design services

and prototyping

In today's rapidly evolving world of technology, design services and prototyping play a crucial role in creating innovative products. Our company specializes in providing professional services in this field, helping to transform your visions into reality.

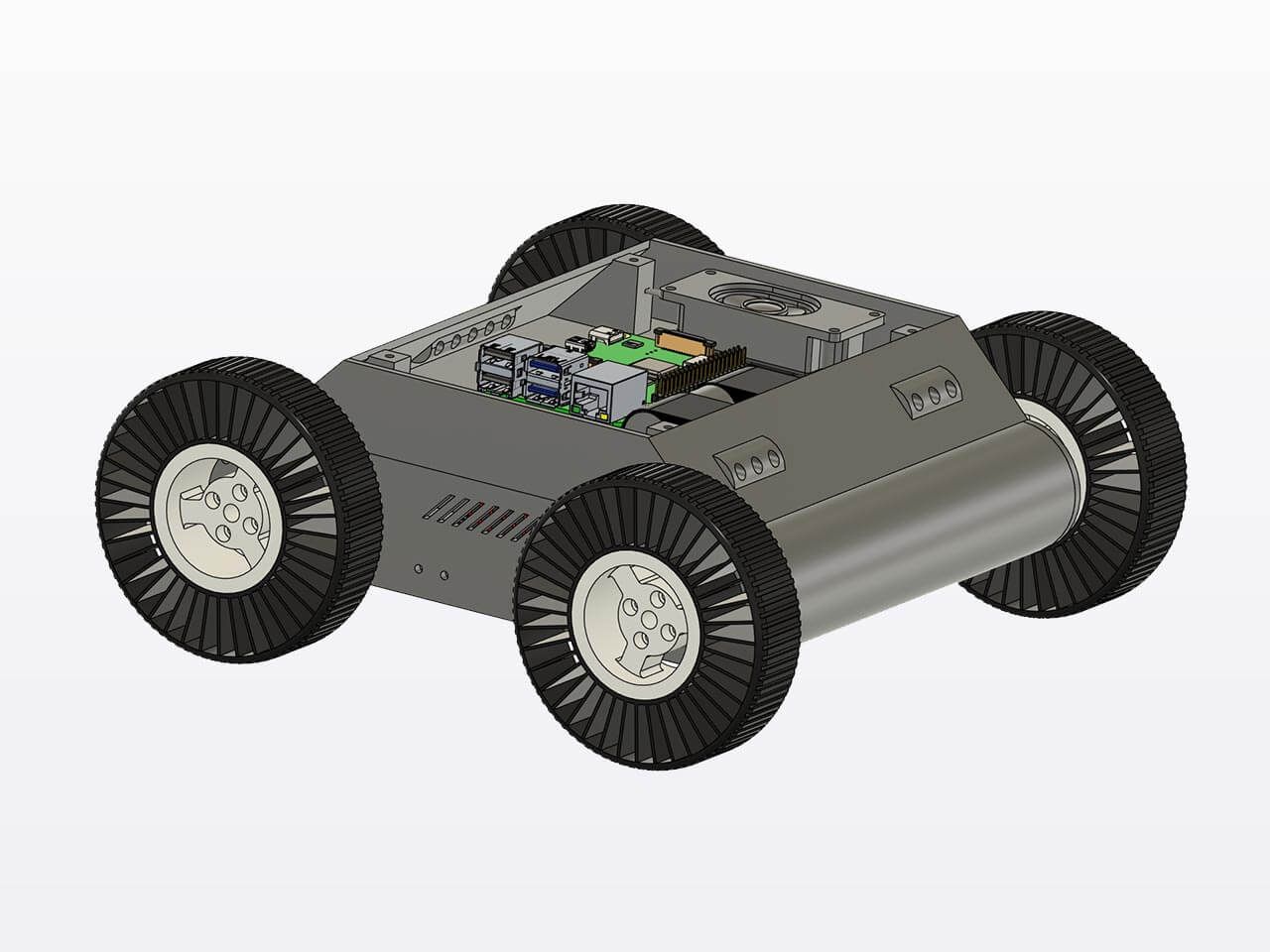

3D design

3D design is the process of creating three-dimensional computer models, which allows for accurate representation of objects in virtual space. This enables not only the visualization of concepts but also the verification of their functionality and feasibility before physical execution. Nowadays, 3D design is used in many industries, from engineering and architecture to entertainment and medicine. Thanks to advanced computer programs such as Autodesk Fusion, Blender, or 3ds Max, designers can create complex models that can then be used to create prototypes, animations, or even computer games.

The 3D design process begins with the creation of a conceptual sketch, which is then transferred to a digital environment. In this environment, the designer manipulates vertices, edges, and polygons to shape the model. Each model consists of a mesh, which is a collection of connected polygons defining the shape of the object. 3D modeling allows for the creation of detailed and realistic visualizations, which can then be used for testing in simulations, presentations to clients, or as a basis for production. Moreover, 3D design is invaluable in the prototyping process, where changes and improvements can be quickly introduced to the project without the need to create costly physical prototypes.

Modern technologies such as 3D printing allow for the rapid and precise creation of physical models directly from digital data, significantly reducing the time and cost of production. 3D design is also a key element in reverse engineering, where existing objects are scanned to create accurate digital models that can then be modified or used to reproduce spare parts. As technology advances, 3D design is becoming increasingly accessible, and its applications continue to expand, opening new possibilities for innovation and creativity in various fields of industry and science.

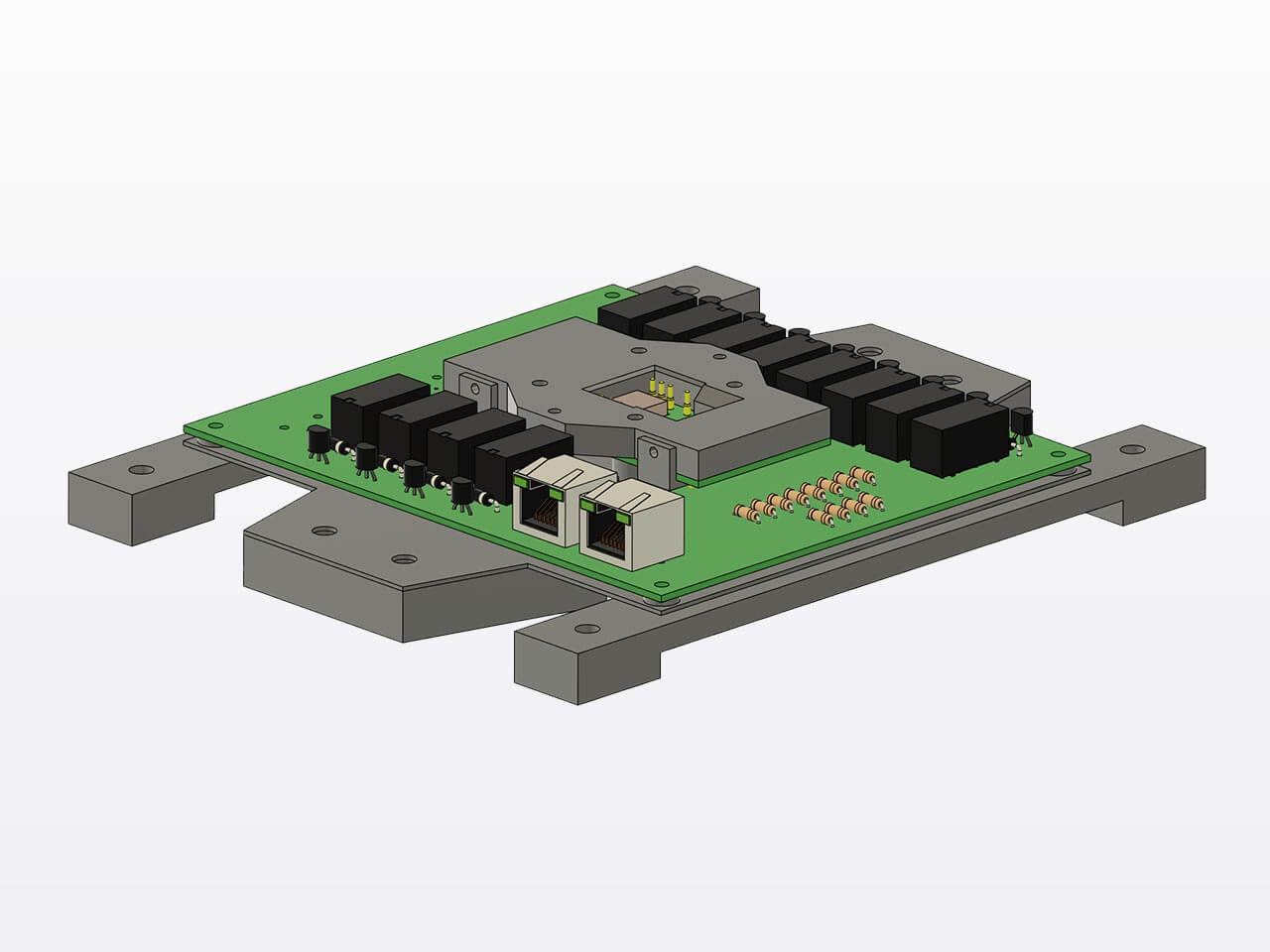

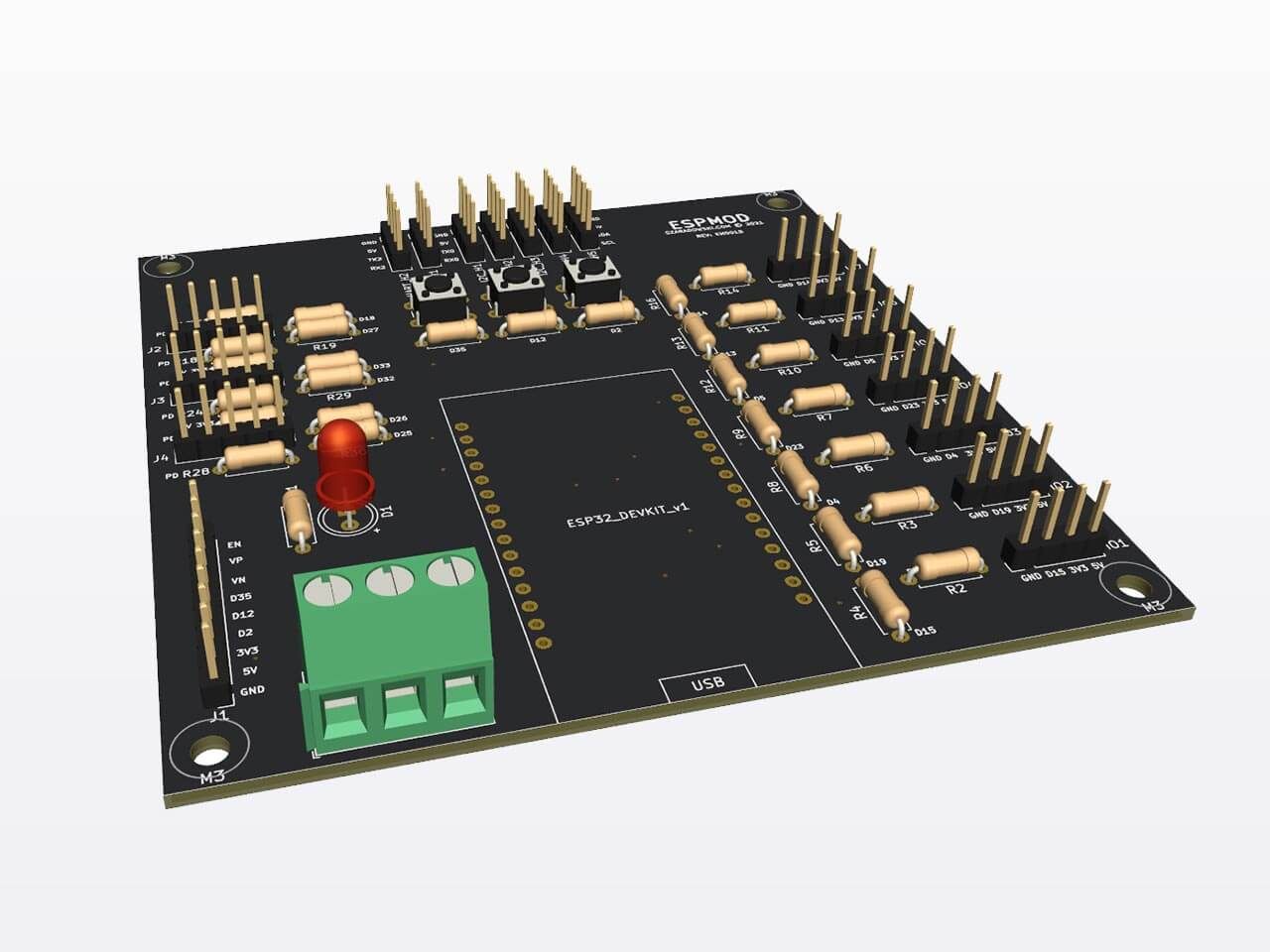

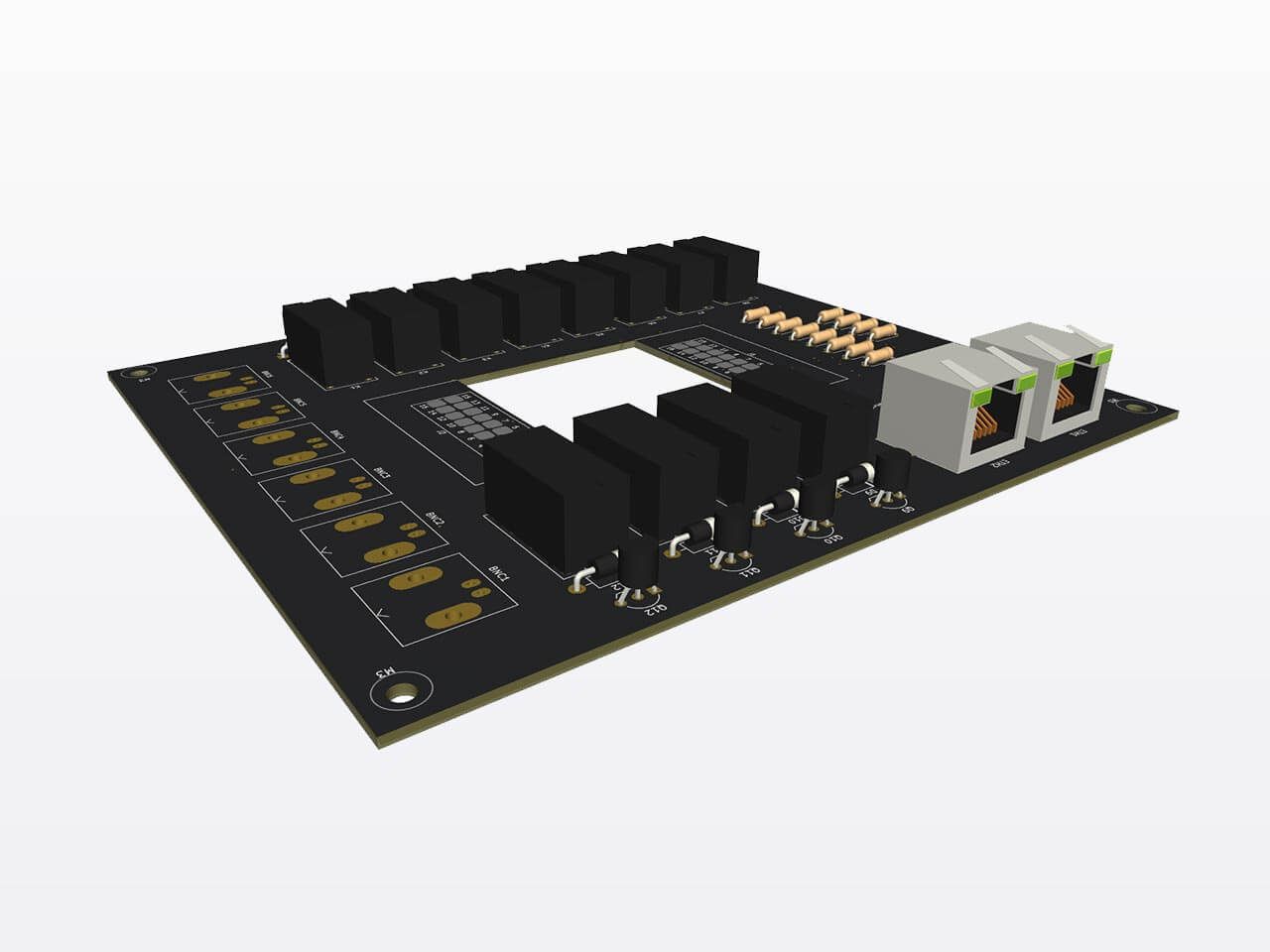

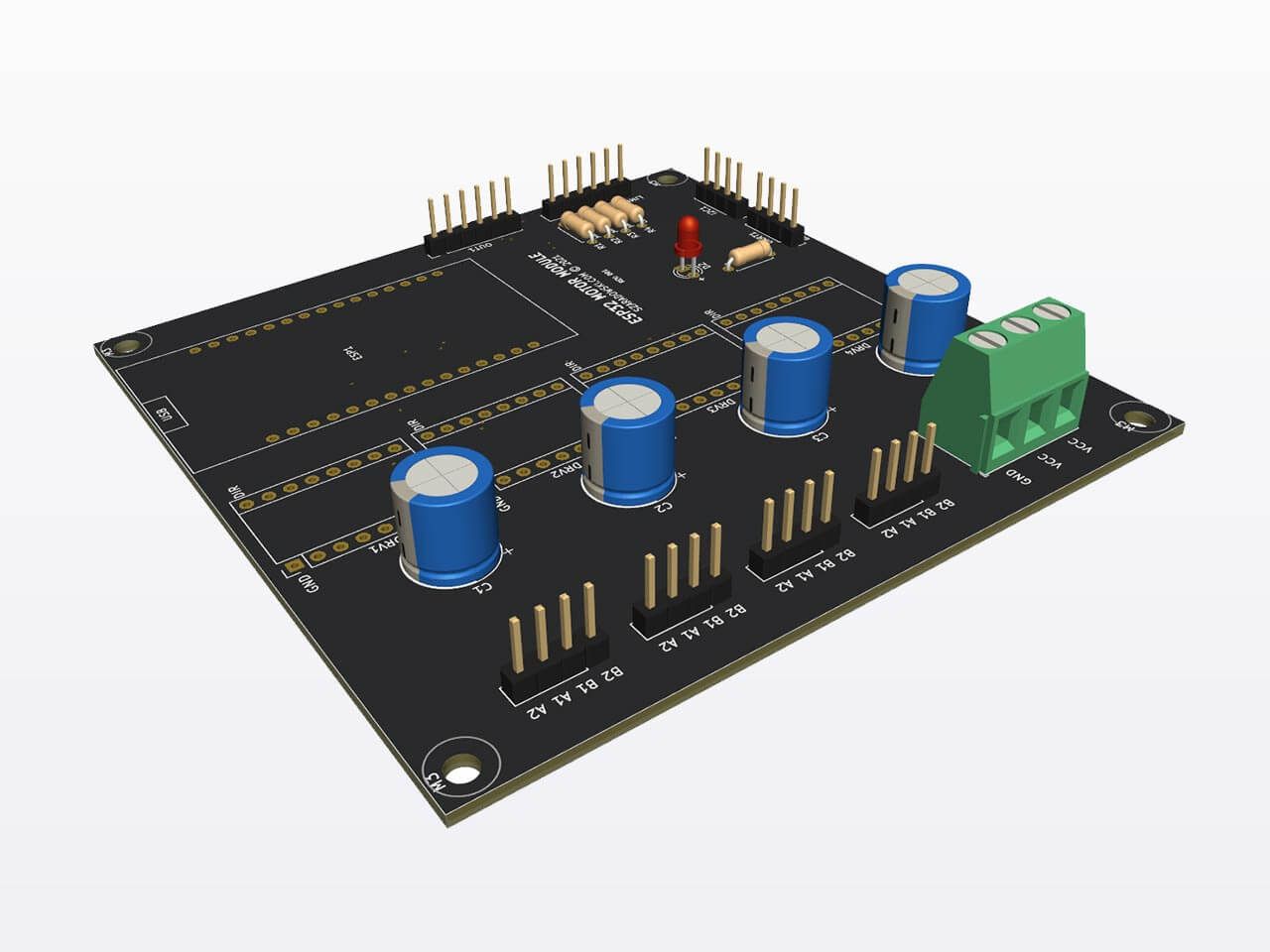

PCB design

Designing and prototyping PCBs (Printed Circuit Boards) are crucial stages in the process of creating new electronic devices. PCB design involves creating electrical schematics of boards that will form the basis for future devices. This is a process that requires technical knowledge and creativity to ensure that the final product is not only functional but also optimized in terms of production costs and efficiency. PCB prototyping then involves the physical execution of the design in the form of a working board, which allows for testing and verification of design assumptions in practice. Thanks to prototypes, engineers can quickly identify potential problems and make necessary corrections before starting mass production.

A key aspect of PCB design is also the choice of appropriate materials and components, which must meet specific quality and reliability standards. Many companies, like Evatronix, offer a wide selection of laminates and technologies, such as FR4, metal substrates, ceramic, and flexible printed circuits, allowing for customization of the product to specific application requirements. Designing multilayer printed circuits is another level of complexity that requires special precision and experience.

The PCB prototyping process is equally crucial as it is at this stage that it is possible to test the functionality of the design and make any necessary corrections. Prototypes allow for verifying whether the electronic circuit works as expected and whether it is ready for mass production. This is the moment when theory turns into practice, and engineers' ideas materialize into physical products.

Design offer and prototyping

Our design services include both the creation of new products and the optimization of existing solutions. We work closely with clients to understand their needs and transform them into tangible projects. Our team consists of experienced designers and engineers who use their knowledge and creativity to meet even the most demanding challenges.

Prototyping is another stage where our company demonstrates its value. We create functional models that allow for thorough testing and evaluation of the project before starting mass production. This crucial step ensures that the final product will meet the expectations and requirements of the end-users.

We invite you to collaborate with us. We offer a personalized approach to each project, flexibility in operation, and a guarantee of satisfaction with the final product. Whether you need a prototype of an electronic device, a mechanical component, or an innovative user interface, we are here to help you transform your ideas into reality.

Check out our offer and join the group of satisfied customers who have trusted our experience and professional approach.

Do you have questions or feedback? We are happy to answer them.

How quickly can I receive a prototype?

The standard completion time is 2-4 weeks, but depending on the complexity of the project and the availability of materials, we are able to deliver a prototype even sooner.

Can I count on support after the project is completed?

Of course, our company provides full technical support and advice on further development and optimization of the product.

What are the costs of services?

Costs are calculated individually for each project, depending on its complexity, requirements, and the number of prototypes. We prepare an individual quote, taking into account the specifics of the order.